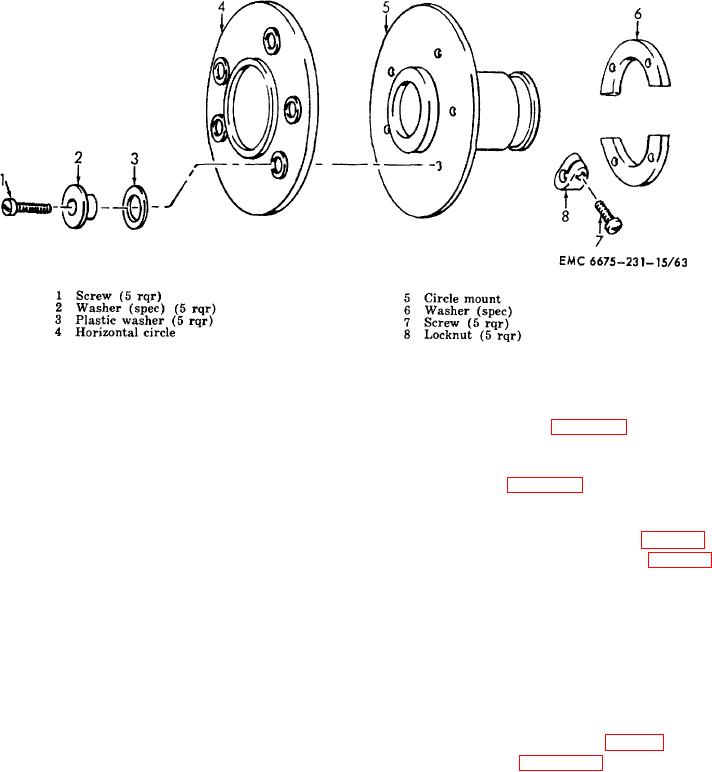

Figure 65. Horizontal circle, disassembly and reassembly.

(6) Straighten all dents and replace all

(3) Clean the horizontal circle with a lens

damaged parts that cannot be repaired.

cloth or lens tissue. Inspect the circle for

chips, cracks, or other damage. Inspect

d. Reassembly. Refer to figure 65 and reassemble

the teeth of the circle mount for wear,

the horizontal circle.

burs, and damage.

e. Installation.

(4) Inspect the clamp ring, contact ring, and

(1) Refer to figure 64 and install the outer

outer vertical axis for dents, cracks, and

vertical axis, contact ring, clamp ring, and

other defects.

horizontal circle.

(5) Inspect the ball bearings for wear,

(2) Install the horizontal clamp (par. 114).

scratches, rust, and other defects.

(3) Install the inner vertical axis (par. 126).

Section XIV. LEVELING SCREWS, HORIZONTAL CIRCLE DRIVE, ILLUMINATION

SOCKET, AND HORIZONTAL CIRCLE HOUSING

It also supports the U-standard and contains the

116. General

horizontal circle and vertical axis.

The leveling screws are the means by which the

117. Leveling Screws

theodolite is precisely leveled as indicated by the plate

a. Removal and Disassembly.

level. The horizontal circle drive is used to rotate the

horizontal circle to any desired position without rotating

(1) Remove the star plate (par. 54).

the U-standard. The illumination socket, located on the

(2) Refer to figure 66 and remove and

circle housing, provides a mount for the horizontal circle

disassemble the leveling screws.

illumination mirror and for the light housing when the

b. Cleaning, Inspection, and Repair.

electrical illumination system is utilized. The horizontal

(1) Clean all parts with an approved cleaning

circle housing comprises the lower part of the theodolite

solvent and dry thoroughly.

to which the leveling screws and star plate are mounted.

(2) Inspect the threaded surfaces on the point

screw, knob, and nut for wear

79

AGO 5078A