TM 5-6675-348-13&P

a.

Installation.

Ensure 130G Grader is on level ground, all hydraulic implements are lowered to the

ground, transmission control is moved to Neutral, and the lock and emergency brake are

engaged. Failure to comply could result in serious injury to personnel.

Do not work on hydraulic oil while oil is hot. Failure to comply could result in severe

injury to personnel.

Prolonged contact with lubricating oil, MIL-L-2105, may cause a skin rash. Skin and

clothing that come in contact with lubricating oil should be thoroughly washed

immediately. Saturated clothing should be removed immediately. Areas in which

lubricating oil is used should be well ventilated to keep fumes to a minimum.

Hydraulic oil is slippery and can cause falls. To avoid injury, wipe up all spilled hydraulic

oil with rags.

Remove hydraulic fill cap to vent pressure from hydraulic tank.

Use Operator's controls to lower all components and relieve hydraulic system pressure.

Failure to comply may result in serious injury or death to personnel.

NOTE

Retain all items (except bench stock items) removed from 130G Grader for future use.

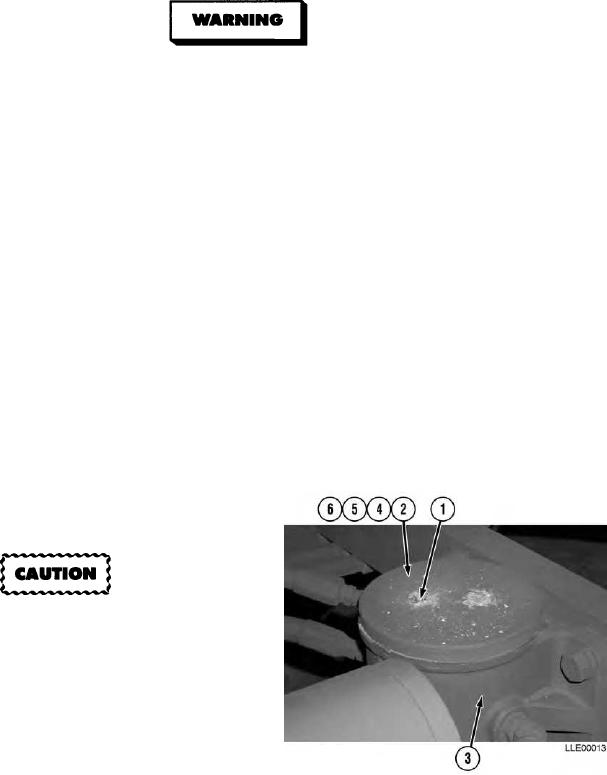

(1)

Remove hydraulic tank fill cap to vent pressure from hydraulic tank (TM 5-3805-261-10).

(2)

Install hydraulic tank fill cap.

(3)

Remove two screws (1) and Hydraswivel

plate (2) from Hydraswivel (3).

Install Hydraswivel Gaskets and Hydraswivel

Shims in same manner as removed or damage

to equipment could result.

(4)

Remove two Hydraswivel Gaskets (4) and (5)

from Hydraswivel plate (2).

(5)

Inspect Hydraswivel Gaskets (4) and (5) and

Hydraswivel Shims (6). If damaged, replace.

3-88