4 2 . Ge ne ra l

The tribrach assembly consists of the base

plate assembly, leveling screws, optical plumb-

ing assembly, circular level and tribrach. The

base plate provides a means for securing the

target set to the tripod. Leveling is accom-

plished by means of the leveling screws. Precise

location of the target set over the station point

is verified by sighting through the optical

plummet eyepiece.

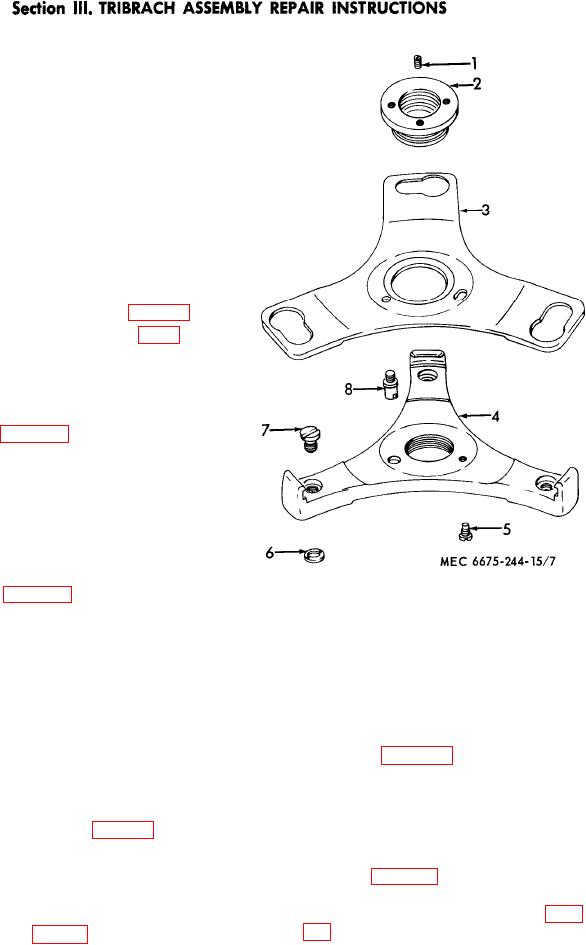

4 3 . Ba se Pla t e Asse m bly

a. Removal and Disassembly.

(1) Remove the tribrach assembly from

the tripod and target set (para 27).

(2) Loosen the lock screw (8, fig. 7) and

push the spring plate (3) clockwise as

far as possible.

(3) Lift the base plate assembly from the

tribrach.

(4) Refer to figure 7 and disassemble the

base plate assembly.

b. Repair and Replacement. Remove burs and

straighten minor dents. Refinish and polish

scratched or scored bearing surfaces. Replace

parts damaged beyond repair with serviceable

parts.

c. Reassembly and Installation.

(1) Refer to figure 7 and reassemble the

base plate assembly.

(2) Position the base plate assembly on

5

Screw, guide

1

Setscrew

6

Nut

2

Nut

the tribrach making sure the feet of

3

Plate, spring

7

Bearing

the leveling screws engage the larger

8

Screw, lock

4

Plate, base

part of the slots in the spring plate

Figure 7. Base plate assembly, disassembly

(3).

and reassembly.

(3) Push the spring plate counterclock-

wise until it engages the leveling

(2) Refer to figure 8 and remove and

screw feet and tighten the lock screw

disassemble the leveling screw.

(8).

b. Repair. Straighten out minor bends and

(4) Install the tribrach assembly on the

dents. File smooth all burs. Replace parts dam-

tripod and target set (para 27).

aged beyond repair with serviceable parts.

c. Reassembly and Installation.

4 4 . Le ve ling Sc re w s

(1) Refer to figure 8 and reassemble and

a. Removal and Disassembly.

install the leveling screw.

(2) Install the loose plate assembly (para

(1) Remove the base plate assembly from

the tribrach (para 43).

AGO 10139A