CHAPTER 3

OPERATOR AND ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section I. OPERATOR AND ORGANIZATIONAL MAINTENANCE TOOLS AND EQUIPMENT

The five-digit code preceding the stock number is the

23. Special Tools and Equipment

Federal supply code number for the manufacturer of the

The special tools required to perform organizational

tool. No special equipment is required by organizational

maintenance on the theodolite are listed in table I and in

maintenance personnel for performing maintenance on

TM 5-6675-231-25P.

References and illustrations

the theodolite.

indicating the use of these tools are listed in the table.

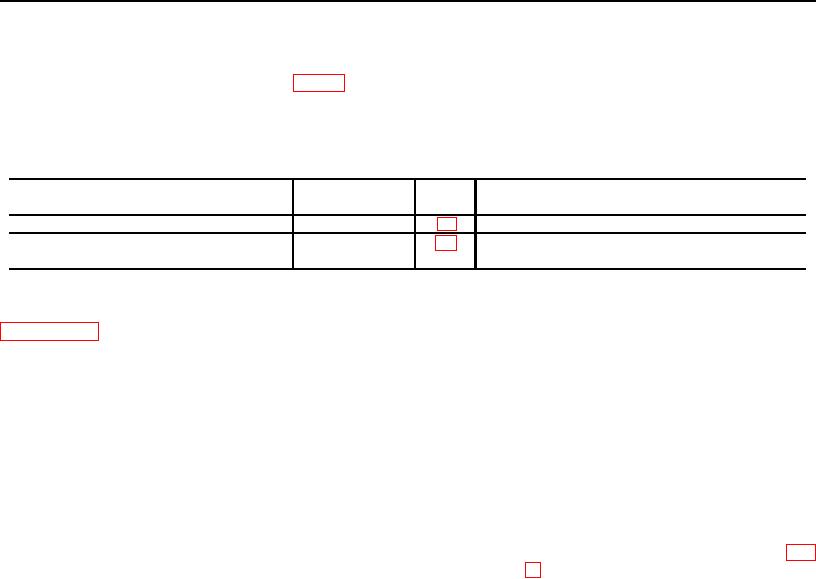

Table I. Special Tools

Item

FSN or part

Figure

Use

No.

No.

Pin, adjusting

6675-353-4103

Adjust theodolite adjusting screws.

Wrench, tripod

5120-429-2949

Tripod

leg

adjustment,

removal

and

installation.

24. Basic Issue Tools and Equipment

25. Organizational Maintenance Repair Parts

Tools and repair parts issued with or authorized

Organizational maintenance repair parts are listed

for the theodolite are listed in the basic issue items list

and illustrated in TM 5-6675-231-25P.

Section II. LUBRICATION

Approved lubricants are non-corrosive, highly refined,

26. General Lubrication Information

and must be free from all paint removing ingredients.

All moving parts of the theodolite, both smooth and

Ordinary machine oil is not an approved lubricant. The

threaded surfaces, are fitted within extremely fine

following lubricants are approved for use on this

tolerances. For this reason,, most parts of the theodolite

theodolite:

are cleaned prior to lubrication. Any attempt to lubricate

the theodolite without first cleaning it may result in

(1) OCW; oil, clock and watch.

damage to the instrument.

Only those lubricants

(2) GL; grease, aircraft and instrument.

approved for use on the theodolite will be used. No

c. Components Requiring Lubrication.

lubrication will be performed in the field unless

(1) Telescope axle bearing. Clean the area

specifically called for.

between the right side axis bearing (fig.

1), vertical clamp, and telescope axis.

27. Detailed Lubrication Information

Apply 1 drop of oil at the top of each

a. Care of Lubricants. Special care should be

crack. Turn the telescope 180 and apply

taken to see that all surveying-instrument lubricants are

1 drop of oil in the same cracks. Rotate

kept absolutely free from contamination by any foreign

the telescope and simultaneously press

substance. Containers must be stored in a clean, dry

down and release the vertical clamp to

place and wiped free of dirt or dust before they are

work the oil into the telescope axis. When

opened. All lids or bottle tops must be airtight.

the axis is

b. Lubricants. No lubricants other than those

approved for use on the theodolite will be stocked.

AGO 5078A 32