TM 10-4510-206-14

TO 40P1-6-2-1

Item

No.

13

14

15

16

17

18

Table 2- I. Preventive Maintenance Checks and Services - Continued

Interval

During

During

During

During

During

After

Location

Item to

Check/

Service

Fuel Pressure

Gage

Fuel Lines

Mixing Valve

Temperature

Gage

Mixing Valve

Shower Stand

Assembly

Shower Heads

Water Hose

Assemblies

Procedure

Check fuel pressure gage ( 17) for

operating pressure. Maintain 90 psi

(620 kPa) to 100 psi (690 kPa).

Inspect all fuel lines (18) for

leaks and for kinked or crushed

lines.

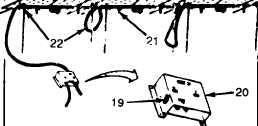

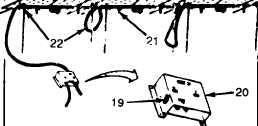

Inspect temperature gage (19) for

broken glass, damaged indicator,

or loose fitting.

Inspect mixing valve (20) for

loose, damaged, or leaking

fittings.

Check for defective shower

heads (21 ) and couplings (22).

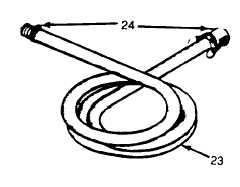

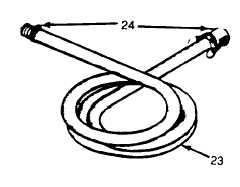

Check hoses (23) and connections

(24) for cracks, leaks, or

collapsed lines,

Not Fully

Mission

Capable if:

Proper pressure

cannot be

maintained.

Fuel lines are

leaking or

damaged.

Gage is loose

or damaged.

Valve is damaged

or leaks.

Damaged or

clogged shower

heads or leaking

connectors.

Leaking or

damaged hose or

connections.

2-8.4

Change 6